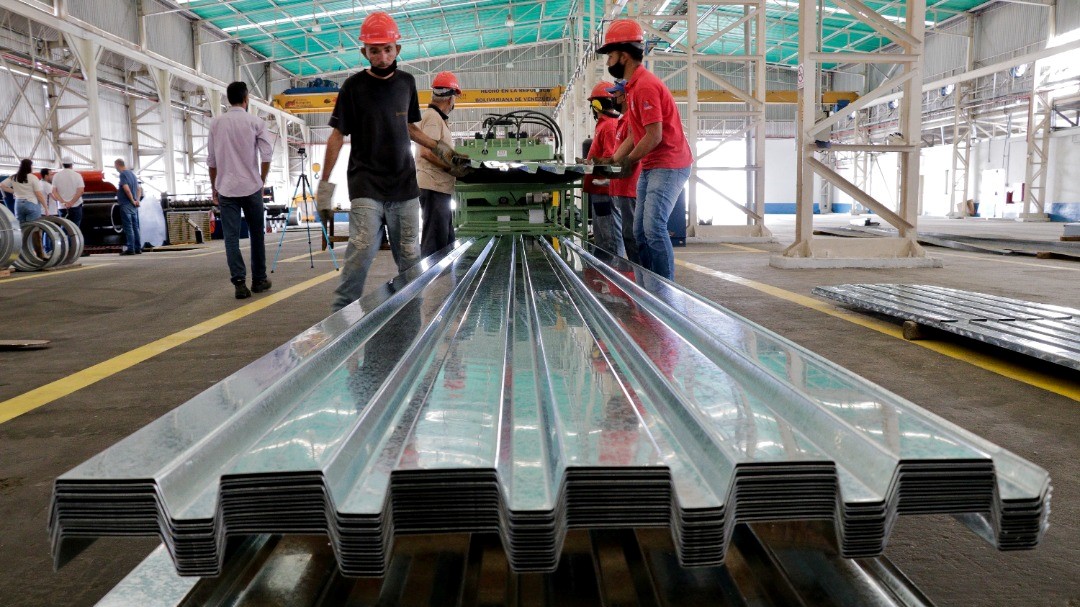

The Metallic Structures Factory (FEME) Tinaquillo, located in Cojedes State, began production tests of metalized soffit sheets for roofs and mezzanines, which have a greater adhesion capacity to concrete.

To substitute imports, the plant, which is attached to Corporación de Industrias Intermedias de Venezuela S.A. (Corpivensa), recently started production tests of metalized soffit sheets for roofs and mezzanines, which have a greater capacity to adhere to the concrete. (Corpivensa), has recently carried out reverse engineering processes in its machinery to offer better products for the country’s construction sector.

In the first phase, it manufactured 150 sheets of soffit for roofs and mezzanines. According to the plant’s operating manager, Rafael Ortega, each was 6 meters long by 90 cm wide.

On the other hand, Ortega detailed that they executed a second test to manufacture a thinner sheet without galvanizing. To have two sheets with different characteristics; to observe the machine’s behavior and performance.

“We ran the first test with raw galvanized steel, 21 gauge, for which we took into account the behavior of the machinery, time, density, and processing speed, resulting in the execution of 75 sheets per coil. In other words, the plant is 100% operational and can manufacture 150 curved sheets in one hour, using 7 tons of material”, explained Ortega about the process.

Finally, he emphasized that thanks to the work of the president of Corpivensa, Michelle Di Lorenzo, and the strategic alliances with sectors of the Venezuelan economy, it has been possible to execute this test plan with a positive balance. Allowing the manufacture of a product with national labor is extremely attractive for the potentiation of the Gran Misión Vivienda Venezuela and the development of the local industry.

Corpivensa Press